Physiological principles of technology of humic preparations on the example of potassium humate

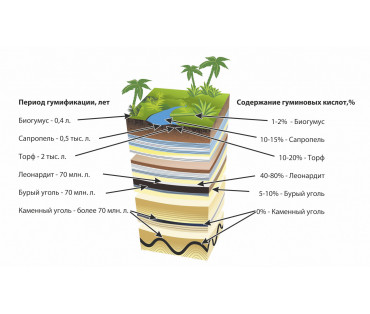

Based on a large number of works in the World (including L.A. Khristeva), it can be concluded that the use of humic preparations, which have been studied until recently, has a double meaning.

On the one hand, they affect the physical and chemical properties of the soil, on the other hand, they directly affect the vital activity of higher plants and microorganisms.

The nature of the action of humic fertilizers depends on their physical and chemical state. If humic fertilizers are applied in large doses, humic acid in them is in the form of a gel or passes under the influence of interaction reactions with the soil, then they improve the chemical and physicochemical properties of the soil. If they are introduced in small doses in an ion-dispersed state and remain in the soil in this state, then humic acid is absorbed by higher plants, is included in the metabolism of the plant organism, improves oxygen supply and increases the vital activity of this organism.

In both cases, the result is an increase in crop yields.

With the local application of fertilizers containing humic acid in such a physical and chemical state to the soil, when it exhibits sorbent properties, a third way to increase productivity is also possible. This principle is that humic substances, adsorbing substances from the soil, improve the nutritional regime of the plant and microflora.

Depending on the properties of the soil and the biochemical characteristics of plants, one or the other side of the action of humic fertilizers will prevail. On soils with poor physical and physico-chemical properties - the first and third, and fertilizers on such soils should be applied in a gel state in large doses under plowing or in small doses locally.

On soils with better physical properties, containing a lot of calcium and therefore poor in the mobile form of humic acids, the use of soluble humic fertilizers in small doses has the advantage.

On sandy soils, it is rational to use all types of humic fertilizers. These soils, as is known, are extremely poor in humus, have poor physical properties and a low absorption capacity, and there are no physiologically active substances in the soil, the representatives of which are soluble humic and fulvic acids.

This work is devoted to the development of issues of technology of humic fertilizers, the main factor of which is soluble humic, fulvic and ulmic acid.

Physiologically active properties of potassium humate. Tasks of technology of humic fertilizers

Potassium humate + Phosphorus "Agro.Bio" in the ion-dispersed state and in concentrations of thousandths and ten thousandths of a percent stimulate the growth of plants, especially the root system, in concentrations above hundredths they inhibit.

The stimulating effect of Potassium Humate + Phosphorus "Agro.Bio" is based on the fact that, being in an ion-dispersed state, it is absorbed by higher plants and used by them at certain stages of development to enhance the phenolase oxidative system. The degree of manifestation of the stimulating effect of humic and fulvic acids on the vital activity of higher plants is associated with the level of mineral nutrition. The lack of nitrogen in the composition of mineral food limits its physiological effect, and a slight decrease in the level of phosphate nutrition even increases it.

The physiological effect of small doses of Potassium Humate + Phosphorus "Agro.Bio" is especially noticeable at the initial stages of development.

The main technological tasks follow from these physiological provisions:

- regulation of the solubility of humic and fulvic acids in raw materials and the selection of appropriate components for this purpose;

- a combination in a single complex of sources of mineral and organic food that can satisfy the need for plants in the early stages of development.

Experience has shown that the solution to this problem can be twofold, namely:

obtaining soluble humates and applying them in the form of a solution together with other fertilizers, or obtaining organo-mineral fertilizers, which, along with mineral elements, would contain such forms of humates that gradually pass into solution in the concentration necessary for the plant.

Production of soluble humates for fertilizer

Taking into account the quality and usefulness, it turned out to be the most expedient to choose Potassium Humate + Phosphorus "Agro.Bio" for fertilizer . We set ourselves the goal of finding a method of production in which the resulting product could be transported in a concentrate and then converted into a solution on site.

The yield on the biological activity of potassium humates during this treatment is illustrated in Table. 1 .

Table 1

Biological activity of aqueous extracts of potassium humate treated with 5% K aOH solution

Growth rates of the root system of barley seedlings | Control. distilled water | Extraction at boil 1 | Hoods in the cold | Boiling extractor V | Hoods in the cold | |||

II | III | IV | ||||||

WE | VII | |||||||

The average length of the roots of 1 seedling in cm | 7.9 | 18.6 | 20.1 | 18.2 | 15.4 | 18.0 | 13.1 | 16.7 |

The number of roots of the II order per 1 plant | No | 68 | 50 | 42 | 35 | 79 | 35 | 70 |

To determine the biological activity, 5-7-day-old barley seedlings are planted in aquatic cultures according to the scheme: 1) distilled water, 2) 0.001% potassium humate solution. The sample is considered positive when the difference between the average length of the roots of plants planted on potassium humate and planted on water exceeds the mean square error of the variant by at least 3 times. The average is derived from 6 measurements. Measurements on the 14th day of the experiment.

The given data show that practically potassium humate can be extracted with water up to 10 times, subjecting it to double boiling, while the yield of humic acid from 1 kg of raw material in terms of 1 ° C solution will be 10 liters.

Therefore, we will only point out that two or three times the application of potassium humate with irrigation water at a concentration of 0.001-0.002% increases the yield of vegetables by an average of 20% and improves the growth of afforestation crops.

All this indicates the prospects for the use of Potassium Humate + Phosphorus "Agro.Bio" as a fertilizer in many regions of Ukraine. At the same time, it should be taken into account that its use has a number of limiting factors, namely: the studied fertilizer can be used only under irrigation conditions, its effect is short-term, since it does not accumulate in the soil, in soils rich in soluble divalent and trivalent salts. metals, it will turn into an indigestible form and become inactivated.

All this raises the question of creating such a form of humic fertilizer in which humic acid, dissolving in the required concentration, would gradually pass into solution throughout the entire growing season, combined with mineral food.

Production of organo-mineral humic fertilizers

Setting ourselves the task of developing such types of humic fertilizers, the main factor of effectiveness of which is the presence of small amounts of soluble humic acid in them, we came to the conclusion that the main principle of the technology of humic preparations should be the regulation of the solubility of humic acids in raw materials. Our work has shown that the optimal concentration of humic acid in solution for plant life occurs at pH 7.2–7.3 . Therefore, the main criterion in the development of new forms of humic fertilizer was the regulation of its reaction to the specified pH.

Considering that the action of humic acid is most effective in the initial period of plant development, and also that the participation of humic acid in the nutrition of higher plants does not exclude mineral food, but only supplements it, we tried to enrich our fat with a small amount of nitrogen and phosphorus, which could would be used by the plant together with humic acid only in the initial period of its development. It turned out that it is most convenient to use nitrogen (N) and aqueous superphosphate for this purpose. Being regulators of solubility, they can at the same time serve as a food source for the plant.

The characteristics of the fertilizers with which vegetation experiments were laid are presented in Table. 2 .

Vegetation experience with these fertilizers was laid on April 23, 2018.

He mainly pursued the following goals: to experimentally confirm the value of the solubility of humic acids in organic-mineral fertilizer and to find the optimal combination of components for their preparation.

The experiment was set up in 2 versions: in the first version, all fertilizers containing phosphorus were applied at the rate of 0.25 g P 2 O 5 per container of 6 kg of air-dry soil, and those not containing - in the same weight amount. Fertilizers were mixed before stuffing with the entire volume of the soil.

In the second variant, fertilizers were applied in an amount ten times smaller, and were given only for seeds. Experimental culture - barley, threefold repetition. Watering up to 60% of full capacity. The accuracy of the experience is 2.1%.

From table 3 , which shows the yield data of this experiment, it can be seen that when applying fertilizers in terms of the content of P 2 O 5 in them at the rate of 9.25 g per vessel, granular organo-mineral fertilizers gave the best results. Granules neutralized to a slightly alkaline reaction in all cases, with the exception of preparation 5/3, where they were more effective than not neutralized. Of the neutralized granules, 2/3 gave the best results, and 5/3 gave the worst results.

These conclusions generally coincide with the conclusions from that part of the experiment, in which Potassium Humate + Phosphorus "Agro.Bio" was applied under seeds in an amount 10 times smaller. Higher efficiency in this case was given by preparations 1/3 and 5/3.

table 2

drug number | Fertilizer preparation method | pH of water extract | % water-soluble P 2 O 5 | %water-soluble NH 3 |

2/ III | Raw material treated with NH 4 OH and superphosphate without plaster removal | 7.2 | 0.64 | 0.72 |

1/ III | The raw material is treated with NH 4 OH and an aqueous extract from superphosphate, i.e. with the removal of gypsum | 7.3 | 0.65 | 0.80 |

4/ III | Raw materials treated with NaOH and superphosphate without removing plaster | 7.2 | 0.56 | — |

5/ III | The raw material is treated with NaOH and an aqueous extract from superphosphate, that is, with the removal of gypsum | 7.3 | 0.54 | — |

0 | Raw materials mixed with superphosphate without alkali pre-treatment | 5.0 | 2.29 | — |

Note: 1) the variant with the removal of gypsum was achieved by obtaining an aqueous extract from superphosphate.

Table 3

Efficiency of humic fertilizers depending on the production method

( According to the vegetative experience of 2018 with barley)

drug number | Fertilizer preparation method and water extract pH | Fertilizers applied | |||

For the whole vessel | Under the seeds | ||||

Yield in % to control | Yield in % to control | ||||

grain | straw | grain | straw | ||

— | Without fertilizer | 100 (7.2)* | 100 (7.8)* | 100 (7.2)* | 100(7.8)* |

0 | Superphosphate granulated, mineral (factory) | 121 | 135 | 111 | one hundred |

2/3 | Raw materials mixed with superphosphate without alkaline pre-treatment, pH-5.0 | 149 | 162 | 119 | 115 |

1/3 | Raw materials treated with NH 4 OH and superphosphate without gypsum removal pH-7.2 | 222 | 245 | 137 | 127 |

— | The raw material is moistened with NH 4 OH and an aqueous extract from superphosphate, that is, with the removal of gypsum. pH-7.3 | 200 | 223 | 161 | 160 |

4/3 | Superphosphate granulated mineral + NH 4 NO 3 (equivalent to preparation 1/III) | 188 | 226 | 131 | 136 |

5/3 | Raw materials treated with NaOH and superphosphate without gypsum removal, pH-7.2 | 170 | 177 | 111 | 103 |

Raw materials are treated with NaOH and water extract from superphosphate. that is, with the removal of gypsum pH-7.3 | 140 | 154 | 150 | 154 | |

Granules of raw materials without superphosphate and neutralization, pH-6.5 | 108 | 105 | 112 | 103 | |

Raw material granules are neutralized with NaOH to pH-7.2 | 172 | 174 | 119 | 115 | |

6/4 | Raw material granules are neutralized with Na 3 PO 4 to pH-7.2 | 143 | 154 | 137 | 130 |

Granules of raw materials with a natural reaction, PH-7.2 | 180 | 172 | 140 | 126 | |

* Shown in parentheses is weight in grams per vessel.

The results obtained can be explained by the role of soluble humic and fulvic acids in plant nutrition. In the case when the test preparations were introduced according to the content of phosphorus in them, and its content in the sample was insignificant, they had to be given in large quantities. Consequently, a larger amount of soluble humic and fulvic acids also got into the vessel. Since with an increase in the concentration of soluble humic and fulvic acids above a certain limit, their effectiveness decreases, it is quite natural that in the first variant the best results were given by those preparations in which the solubility of humic acids was lower. This fertilizer was preparation 2/3. Gypsum was not removed in it, and therefore part of the acids formed calcium humates and passed into an insoluble state, while the amount of soluble humates decreased, approaching the optimum.

In the second variant, where fertilizers were applied in quantities 10 times smaller, the picture was reversed. A higher effect was given by those preparations from which the gypsum was removed. Obviously, these preparations, provided they were applied in smaller doses, contained the amount of soluble humic and fulvic acids that more closely matches the needs of the plant. In general, the results of this experiment confirmed the importance of regulating the solubility of humic and fulvic acids in the effectiveness of organo-mineral fertilizers and made it possible to find the best option for such a fertilizer.

It should be emphasized that the above calculations can in no case be mechanically transferred to other types of raw materials. They need to be restored experimentally.

Vegetation experiments conducted in 2019 showed that the effectiveness of Potassium Humate + Phosphorus "Agro.Bio" does not depend on what was spent for its manufacture - phosphoric acid or an aqueous extract from superphosphate. Moreover, when in the production experiments of 2020, in the manufacture of Potassium Humate + Phosphorus "Agro.Bio", instead of an aqueous extract from superphosphate, powdered superphosphate was used from the same approximate calculation, it turned out that this preparation was only slightly less effective than obtained by water extraction. Obviously, such an amount of calcium that is introduced into potassium humate from 6-8 kgsuperphosphate per centner of fat. causes a significant coagulant and humic acids does not significantly affect their digestibility. (In the vegetative experiment described above, 24 kg of superphosphate were given for 1 quintal of fat): Nevertheless, it should be noted that the option when potassium humate is prepared by wetting with an acid solution has an advantage . First of all, it affects the uniformity of the chemical composition of the fertilizer.

The chemical composition of potassium humate and factors of its effectiveness

For production testing of humic fertilizers, which were produced in the Kherson region in 2019 and 2020, trial batches of Potassium Humate + Phosphorus "Agro.Bio" were made . The data of the analysis of these fertilizers are given in Table 4 . They show that the content of digestible forms of phosphorus and nitrogen were approximately the same in all batches.

It should be noted that phosphorus in potassium humate is somewhat unevenly distributed, which depends on the size of the fertilizer particles. It was more in smaller factions. Table 1 illustrates the average chemical composition of the mineral part of potassium humate . 5 .

Table 4

The content of digestible forms of nitrogen and phosphorus in the humophos of various production methods

(In % per sample at moisture at the time of manufacture)

Content in % | Humophos was produced | |||

2019 | 2020 | |||

Average sample | Party 1st | Party 2 | Party 3 | |

Humidity | 48 | 43 | 54 | 59 |

N hydrolysable in 0.5 n H 2 SO 4 | 0.33 | 0.32 | 0.29 | 0.32 |

P 2 O 5 soluble in 0.5 n H 2 SO 4 | 0.89 | 0.97 | 0.63 | 0.67 |

Note: In 2019, phosphoric acid was used to prepare humophos, and in 2020, superphosphate was used.

Table 5

Average chemical composition of potassium humate

(in % for a completely dry sample)

Component name | Component Shape | Content in % |

Nitrogen (N) | General content | 3.52 |

Soluble in 0.5 n H 2 SO 4 | 0.65 | |

Phosphorus (P 2 O 5 ) | General content | 1.92 |

Soluble in 0.5 p H 2 SO 4 | 1.78 | |

Water soluble | 0.82 |

Note: N was determined by the Kjeldol P 2 O 5 weight method according to Lorentz.

From this table it can be seen that the total nitrogen content in it rather slightly exceeds the phosphorus content. However, if we compare the amounts of these components in digestible form, then the picture is reversed . The data obtained can be explained as follows: peat, which serves as a burnt raw material for the production of Potassium Humate + Phosphorus "Agro.Bio" , contains only about three percent nitrogen and half a percent of phosphorus, and almost all of this nitrogen is in an inaccessible form, while phosphorus dissolves better, with in the production of Potassium Humate + Phosphorus "Agro.Bio", as mentioned above, raw materials are processed with a small amount of nitrogen (N). There is reason to believe that this nitrogen binds primarily to the carboxyl groups of humic acids and then is easily hydrolyzed by 0.5 n H 2 SO 4.

When treating the fat with phosphoric acid, the reactions probably proceed as follows: phosphoric acid reacts first of all with some amount of nitrogen or ammonium humate, and then with the raw material itself. As a result of these reactions, potassium humate is enriched with P 2 O 5 , part of which remains in an assimilable form. It was noticed that if raw materials are treated with the same amount of superphosphate without and after nitrogen neutralization, then the amount of water solubility of P 2 O 5 in the second case always decreases. The question arises why superphosphate phosphorus binds more firmly in raw materials pre-treated with nitrogen? The answer can be obtained if we assume that the following reaction takes place in the manufacture of potassium humate:

Sa(N 2 RO 4 ) 2 + N = SaNRO 4 + NH 2 PO 4

From this reaction, we see that part of the water-soluble calcium monophosphate is converted into diphosphate, which, as is known, belongs to acid-soluble compounds.

Due to the fact that we attach great importance to the solubility of humic and fulvic acids in the nature of the effectiveness of organo-mineral fertilizers, a study was made of the forms of humic and fulvic acids in potassium humate. Various solvents and various extraction conditions were tested. The results of this analysis are presented in table. 6 .

Table 6

Solubility of humic and fulvic acids in potassium humate

Solvents | Extraction conditions | |||||

By boiling for 30 min. | At 80° in a water bath for 30 min. | In the cold | ||||

The content of humic and fulvic acid in% on absolutely dry. sample | Solubility drop factor | The content of humic and fulvic acid in °/ 0 on absolutely dry. sample | Solubility drop factor | The content of humic and fulvic acid in% on absolutely dry. sample | Solubility drop factor | |

2%KOH | 32.7 | 1.00 | 27.2 | 0.83 | 3.2 | 0.096 |

0.1% KOH | 21.3 | 0.65 | 19.6 | 0.60 | 2.9 | 0.090 |

0,01%KOH | 0.69 | 0.21 | 0.70 | 6.022 | 0.16 | 0.0048 |

1.001%KOH | 0.36 | 0.011 | 0.38 | 0.012 | 0.065 | 6.0020 |

distilled water | 0.33 | 0.010 | 0.28 | 0.0085 | 0.049 | 0.0015 |

tap water | 0.29 | 0.009 | 0.16 | 0.0049 | 0.035 | 0.0011 |

Note: Potassium humate after treatment with solvents in a ratio of 1: 10 was left for a day, after which the solutions were poured and the content of humic acid was determined calorimetrically. As a standard, we took a solution extracted by boiling with a 2% K OH solution, in which the carbon titer was determined.

The data of this table show that humic and fulvic acid in potassium humate is in a polydisperse state. From an agronomic point of view, it is extremely important that even in the cold, such a quantity of humic and fulvic acid passes into solvents such as water, which can serve as a source of nutrition for physiologically active organic compounds.

Due to the fact that in such a polydisperse system as humic and fulvic acid, mutual transitions from one degree of dispersion to another are always possible, there is reason to believe that as the most soluble forms of humic acid are used, they will be replenished at the expense of other fractions.

As for the other possibility, that is, the reverse transition of humic and fulvic acids from the most soluble forms to the less soluble ones, this danger is not very significant for us, at least for the chestnut soils of southern Ukraine. The fact is that the highly dispersed forms of humic and fulvic acids at low concentrations turned out to be very resistant to coagulation. However, the concentration of digestible forms of humic and fulvic acid, which will be created in the soil solution when potassium humate is added to the soil, primarily depends on the composition of soil cations. This circumstance must be taken into account, both when analyzing the effectiveness of humic preparations on different soils, and when refining the technology for different soils. Our standards have been developed for all regions of Ukraine.

Due to the fact that nitrogen and phosphorus, which are part of humic preparations, are intended to serve as a source of mineral food in the initial period of plant development, it became necessary to establish how these elements will be assimilated by plants.

In order to answer this question, in 2020 a growing experiment was established in sand and soil crops.

The experiment in sand cultures was based on a mixture in which phosphorus was given in the form of a Sorensen buffer mixture. In the mixture, nitrogen and phosphorus were successively replaced by nitrogen and phosphorus of potassium humate. The latter was introduced based on the content of 0.5n H 2 SO 4 soluble forms of these elements in it. In soil crops, fertilizer was given at the rate of 0.15 g of assimilable nitrogen and phosphorus per 1 kg of soil. Mineral fertilizers were applied in the form of ammonium sulfate and superphosphate. All fertilizers in these variants were mixed with the entire volume of soil.

In order to study the effect of the ready-made preparation Potassium Humate + Phosphorus "Agro.Bio" as a growth stimulator or, in the same way, as a source of plant nutrition with physiologically active organic substances, another variant was introduced into the experiment. In it, potassium humate in the amount of 20 g per vessel was applied locally (under the root) against the background of a complete nutrient mixture or according to "NP" in the soil culture. Since this dose of potassium humate contained a certain amount of phosphorus and nitrogen, an additional control was given to this variant, in which minerals, equivalent to their content in potassium humate, were also introduced locally.

Experimental culture - tomatoes, 4-fold repetition, vessel capacity: sand - 12 kg, soil - 9 kg. Watering was carried out up to 70% of the total moisture capacity with tap water. The stuffing of the vessels was done on 13.04. 2020, planting seedlings - May 10. The results of the experiment in sand cultures are presented in table. 7.

Table 7

The effectiveness of potassium humate as a source of nutrition and growth stimulator

(Based on a vegetative experience with tomatoes in sandy crops 2020)

Experience Scheme | Harvest of tomatoes | haulm weight | ||

in g | in % to control | in g | in % to control | |

Potassium humate as a source of nitrogen | 171 | 131 | 234 | 152 |

Mineral control to option 1 | 131 | one hundred | 154 | one hundred |

Potassium humate as a source of P 2 O 5 | 173 | 157 | 208 | 122 |

Mineral control to option 3 | 110 | one hundred | 170 | one hundred |

Potassium humate + Phosphorus "Agro.Bio" as a growth stimulator against the background of the complete mixture of Sorensen | 315 | 173 | 222 | 131 |

Mineral control to option 5 | 182 | one hundred | 170 | one hundred |

Note: The experiment was not brought to full fruiting and removed after the reddening of the fruits of the first brush.

From Table. 7 shows that potassium humate introduced as a source of nitrogen and phosphorus is assimilated by plants no worse than from mineral fertilizers. The fact that the yield according to this variant is slightly higher than the corresponding mineral controls does not give the right to speak about the increased digestibility of these fertilizers by plants, since this phenomenon can also be explained by the fact that potassium humate was introduced based not on the total content of nutrients in it, but on the basis of soluble in 0.5 n H 2 SO 4 .

The influence of Potassium Humate + Phosphorus "Agro.Bio" on the yield of tomatoes was especially sharp when it was applied against the background of a complete nutrient mixture. However, it should be noted that the effect obtained in this variant also cannot be attributed only to the actual stimulating effect of this fertilizer. Another side of the action of humic fertilizers also played its role here, namely, their role as a buffer system with an increase in osmotic pressure in the soil solution.

In this experiment, we observed that the plants of the variant in which potassium humate was applied locally felt great from the very first days after transplanting the seedlings into the vessel, while the introduction of even small amounts of mineral fertilizers under the root depressed the seedlings for quite a long time. The results of the experiment in soil culture are presented in table. 8.

As we see, in general, the data of experiments in soil cultures agree with the data of experiments in sand cultures, and the conclusions of the latter can be extended to this experiment.

We have repeatedly noted that humic and fulvic acids promote the use of phosphorus by the plant. In order to check whether potassium humate has the same effect, another experiment was carried out in sand cultures, in which the phosphorus isotope P 32 was replaced as an indicator .

Table 8

Efficiency of potassium humate as a source of mineral nutrition and plant growth stimulator

(Vegetation experience with tomatoes in soil crops 2020)

Experience Scheme | fruit harvest | haulm weight | ||

in g per vessel | in % to control | in g per vessel | in % to control | |

Potassium humate as a source of nutrition N, P | 370 | 107 | 233 | 91 |

Mineral control to option 1 | 346 | one hundred | 255 | one hundred |

Potassium humate as a growth stimulator against the background of N, P | 506 | 151 | 297 | 110 |

Mineral control to option 3 | 335 | one hundred | 270 | one hundred |

This experiment was laid in parallel with the one described above, according to the same method, only in the variants - potassium humate as a source of phosphate nutrition and mineral control to it, at the time of filling the vessels, P 32 was added in the form of a K 2 HPO 4 salt solution at the rate of 100 ʮ Cu per vessel.

Since the experiment was expected to be brought to fruiting in order to increase the activity of the preparations at the end of the experiment, on July 28 the plants were additionally watered with a solution of K 2 HPO 4 at the rate of 50. Cu per vessel. The impulses in the preparations were counted on July 26 and August 28. The preparations were prepared by drying tissues of various plant organs at a temperature of 110°C. Samples for readings were taken after thorough grinding of the material.

Table 12

The effect of potassium humate on the intake of P 32 in the plant

(Based on experience with tomatoes in sand cultures 2020)

Pulses per 100 mg dry matter per minute

Experience Scheme | Countdown 26/07 at | Countdown 28/08 at | |||||

roots | stems | leaves | fruits | ||||

leaves | |||||||

roots | stems | ||||||

Full mix | 1155 | 1244 | 1510 | 132 | 92 | 118 | 326 |

Nutrient mixture in which the phosphorus of the mixture is replaced by the phosphorus of potassium humate | 1798 | 1091 | 2132 | 200 | 184 | 216 | 710 |

It can be seen that potassium humate not only contributes to the successful entry of phosphorus into the plant, but also affects the distribution of P 32 in its organs. If in an earlier period of development of tomatoes, under the influence of potassium humate, the outflow of P 32 into the leaves increases, then at a later stage of development, when the plant bears fruit, it increases the influx of phosphorus into the fruits.

Related Products

Humate Potassium + Phosphorus «Agro.Bio»

Potassium humate + ballast-free phosphorus from leonardite produced by AGRO.BIO is an environmentally friendly complex fertilizer and growth stimulator for agricultural plants, of organic origin, with..

$7.00

Multicomplex Humate 10

Complex preparation Multicomplex humate 10 - liquid, concentrated, organic fertilizer, plant growth stimulant, containing potassium humate and microelements in chelated form (humic acids - 64.9 ..

$10.00

Related Articles

Basic properties of humates and requirements for humic preparations

Agrobio – humates manufacturing company – has defined seven conceptual provisions on the fundamental properties of humates and requirements to them. Before proceeding with the systematic presenta..

Fulvic acids. Structure, composition and formation of fulvic acids

Fulvic acids (FA) are the mixture of weak organic acids of the aliphatic and aromatic series, which dissolve in water at all levels of pH (sour, neutral and alkaline). Their composition and form ..

The influence of potassium humate Mind Extra and Amino Enegry Agro.bio on the wheat crop in the south of Ukraine

A characteristic feature of hard spring wheat is their high protein content, but in the south of Ukraine they yield a relatively lower yield than winter wheat. Therefore, it is extremely important to ..

Influence of Totem Agro.Bio on the development of grape seedlings

Agro.Bio pays great attention to the further development of viticulture. To successfully solve the problems of developing viticulture, it is of great importance to increase the yield of first-class..

Comparative efficiency of potassium humate and an equivalent set of mineral fertilizers

Trial batches of humic fertilizers were transferred for study and testing to our research center in the Kherson region. We present the results of those field experiments that allow us to judge the ..

Importance of soil organic matter and fertilizers for plant nutrition

For any farm, increasing the efficiency of soil fertility is of great importance.A huge amount of nutrients is concentrated in soils - in humus (humus), organic residues of plant origin and in mineral..

Nutrition of Higher Plants by Organic and Synthetic Compounds and Micronutrients

Plant nutrition is a fundamental issue in agriculture, so clarifying the specifics of what plants consume is one of the most important tasks of agricultural biological science. ..